Quality Buried Zinc Anode

Release time:

2025-07-14

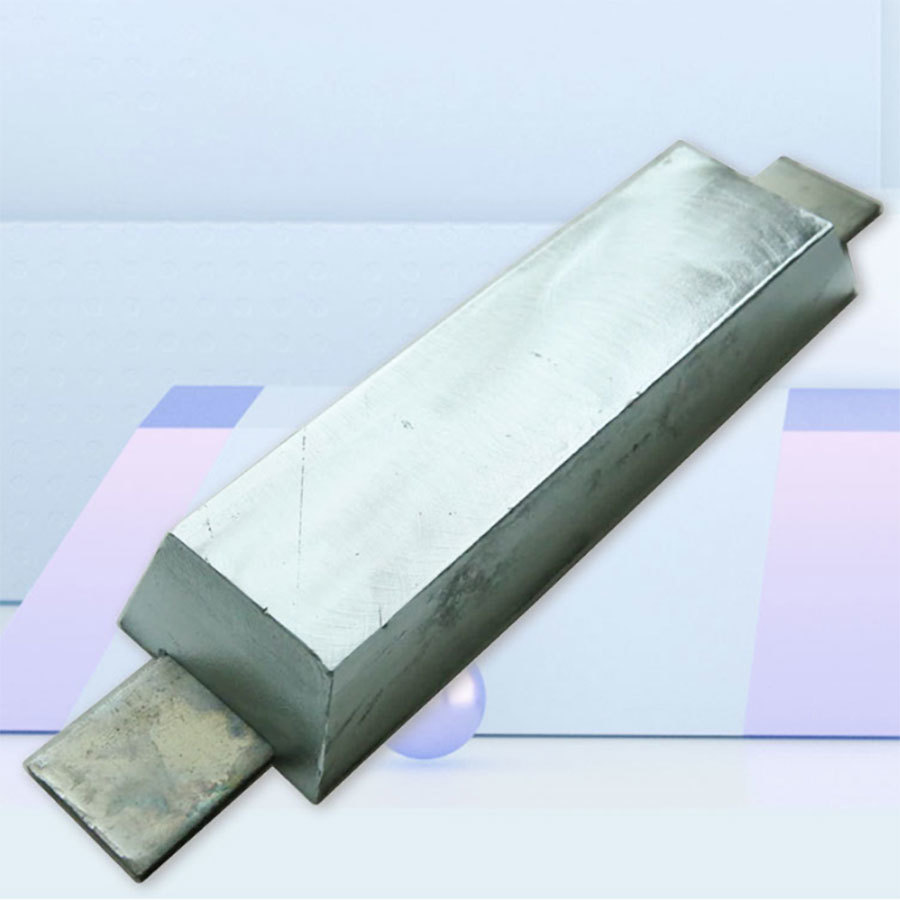

The Quality Buried Zinc Anode is an essential component for effective underground corrosion protection in various industries, including oil and gas, water supply, and infrastructure. Manufactured with premium zinc alloy

Product Parameters

Execution Standard:GB/T4950-2021 GB/T21448-2017

Main Performance: Low anode self-dissolution, high current efficiency, good self-regulation performance of anode current; long protection lifespan, up to 20-30 years, generally no 'over-protection' phenomenon occurs.

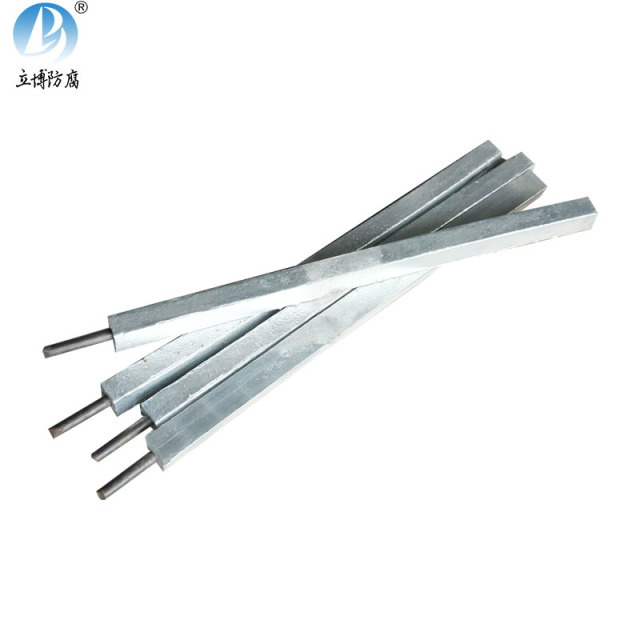

Applicable Scope:Zinc alloy sacrificial anodes are suitable for cathodic protection of metal corrosion in ships, ballast water tanks, mechanical equipment, marine engineering and port facilities, drilling platforms, port docks, condensers, water pumps in seawater media, and pipelines, cables, etc. in low resistivity soil.

Product Features:Zinc-aluminum-cadmium (ZAC) sacrificial anodes are cast from high-purity zinc and aluminum, cadmium alloy. This product is recognized by China Classification Society (CCS), and the quality standard meets GB/T4950-2021. The chemical composition of zinc anodes complies with USMIL-A-18001H and ASTM+B418 (Type 1) standards. The anodes for pipelines also comply with GB/T21448-2017 'Design Specification for Cathodic Protection of Buried Steel Pipelines'. Different specifications and sizes can be customized according to customer requirements!

Quality Assurance

Supports multiple specifications customization

Suitable for various scenarios

Direct delivery from the original factory

Suitable for various scenarios

Low self-dissolution, high current efficiency

Zinc-aluminum-chromium alloy sacrificial anode

Chemical Composition

|

Chemical Elements |

AI |

Cd |

Impurities not greater than |

Zn |

|||

|

Fe |

Cu |

Pb |

Si |

||||

|

Content % |

0.3-0.6 |

0.05-0.12 |

0.005 |

0.005 |

0.006 |

0.125 |

Remainder |

Electrochemical Performance

|

|

Open Circuit Potential |

Working Potential |

Actual Electric Capacity |

Current Efficiency |

Dissolution Status |

|

In Seawater |

-1.09~-1.05 |

-1.05~-1.00 |

≥780 |

≥95 |

Corrosion products are easy to detach |

|

In Soil |

≤-1.05 |

≤-1.03 |

≥530 |

≥65 |

Common Sacrificial Anode Models and Specifications for Hulls

|

Model |

Specification |

Weight (kg) |

|

Length*Width*Height (mm) |

||

|

ZH-1 |

800*140*60 |

47.0 |

|

ZH-2 |

800*140*50 |

39.0 |

|

ZH-3 |

800*140*40 |

31.0 |

|

ZH-4 |

600*120*50 |

25.0 |

|

ZH-5 |

400*120*50 R |

16.0 |

|

ZH-6 |

500*100*40 |

13.6 |

|

ZH-7 |

400*100*40 |

11.0 |

|

ZH-8 |

300*100*40 |

7.5 |

|

ZH-9 |

250*100*40 |

6.5 |

|

ZH-10 |

180*70*40 |

3.5 |

|

ZH-11 |

300*150*50 Double Iron Legs |

14.5 |

|

ZH-12 |

300*150*40 Double Iron Legs |

11.5 |

|

ZH-13 |

300*150*50 Bolt Type |

12.0 |

|

ZH-14 |

300*150*40 Bolt Type |

9.0 |

Common Sacrificial Anode Models and Specifications for Port Facilities and Marine Engineering

|

Model |

|

Weight (kg) |

|

Length*(Upper Base + Lower Base)*Height (mm) |

||

|

ZI-1 |

1000*(115*135)*130 |

115.0 |

|

ZI-1 |

750*(115+135)*130 |

85.0 |

|

ZI-1 |

500*(115+135)*130 |

56.0 |

|

ZI-1 |

500*(105+135)*100 |

40.0 |

Common Sacrificial Anode Models and Specifications for Ballast Water Tanks

|

Model |

Specification |

Weight (kg) |

|

Length*(Upper Base + Lower Base)*Height (mm) |

||

|

ZT-1 |

500*(115+135)*130 |

56.0 |

|

ZT-2 |

1500*(65+75)*70 |

50.0 |

|

ZT-3 |

500*(110+130)*120 |

50.0 |

|

ZT-4 |

1000*(58.5+78.5)*68 |

33.0 |

|

ZT-5 |

800*(56+74)*65 |

25.0 |

|

ZT-6 |

1150*(48+54)*51 |

20.0 |

|

ZT-7 |

250*(80+100)*85 |

13.0 |

|

ZT-8 |

200*(70+90)*70 |

7.5 |

Bracelet Type Zinc Alloy Anode Models and Specifications

|

Model |

Specification |

Weight (kg) |

|

Inner diameter * Width * Thickness * Gap mm |

||

|

ZZ-1 |

1020*200*35*51 |

179.5 |

|

ZZ-2 |

819*60*30*51 |

34.5 |

|

ZZ-3 |

624*80*30*51 |

45.0 |

|

ZZ-4 |

513*100*30*51 |

45.0 |

|

ZZ-5 |

280*250*45*51 |

76.5 |

|

ZZ-6 |

252*250*45*51 |

68.5 |

Common sacrificial anode model specifications for storage tanks

|

Model |

Specification R |

Weight (kg) |

|

Length*(Upper Base + Lower Base)*Height (mm) |

||

|

ZC-1 |

750*(115+135)*130 |

85.0 |

|

ZC-2 |

500*(115+135)*130 |

56.0 |

|

ZC-3 |

500*(105+135)*100 |

40.0 |

|

ZC-4 |

300*(105+135)*100 |

25.0 |

Common long strip sacrificial anode model specifications and common disc-shaped sacrificial anode model specifications for seawater cooling water systems

|

Model |

Specification |

Weight (kg) |

|

Length*(Upper Base + Lower Base)*Height (mm) |

||

|

ZE-1 |

500*(115+135)*130 |

56.0 |

|

ZE-2 |

1000*(80+100)*80 |

50.0 |

|

ZE-3 |

500*(105+135)*100 |

40.0 |

|

ZE-4 |

500*(80+100)*80 |

25.0 |

|

ZE-5 |

400*(110+120)*50 |

16.0 |

|

ZE-6 |

300*(140+160)*40 |

12.5 |

|

ZE-7 |

200*(90+110)*40 |

5.5 |

|

Model |

Diameter * Height (mm) |

Weight (kg) |

|

ZE-8 |

300*60 disc-shaped |

30.0 |

|

ZE-9 |

360*40 disc-shaped |

28.5 |

|

ZE-10 |

300*40 disc-shaped |

20.0 |

|

ZE-11 |

200*50 disc-shaped |

10.5 |

|

ZE-12 |

180*50 disc-shaped |

8.5 |

|

ZE-13 |

120*100 disc-shaped |

7.5 |

Common sacrificial anode model specifications for buried pipelines, storage tank outer walls, and other underground metal structures

|

Model |

Specification |

Weight (kg) |

|

Length*(Upper Base + Lower Base)*Height (mm) |

||

|

ZP-1 |

1000*(78+88)*85 |

50.0 |

|

ZP-2 |

1000*(65+75)*65R |

33.0 |

|

ZP-3 |

800*(60+80)*65 |

25.0 |

|

ZP-4 |

800*(55+64)*60 |

22.0 |

|

ZP-5 |

650*(58+64)*60 |

18.0 |

|

ZP-6 |

550*(58+64)*60 |

15.0 |

|

ZP-7 |

600*(52+56)*54 |

12.5 |

|

ZP-8 |

600*(40+48)*45 |

9.0 |

The Quality Buried Zinc Anode is an essential component for effective underground corrosion protection in various industries, including oil and gas, water supply, and infrastructure. Manufactured with premium zinc alloy, the quality buried zinc anode delivers consistent and reliable electrochemical performance to prevent corrosion of buried metal structures such as pipelines, tanks, and cables. Its high purity and optimized design ensure long service life and efficient current output even in challenging soil conditions. The quality buried zinc anode is easy to install, requires minimal maintenance, and offers excellent durability, making it a cost-effective solution for long-term protection. Trusted by professionals worldwide, this quality buried zinc anode safeguards critical assets, reducing repair costs and enhancing infrastructure longevity. Choose the quality buried zinc anode for reliable, durable, and effective cathodic protection in your underground applications.

Key words:

Learn more about industry dynamics

The company's main products: magnesium alloy sacrificial anode series, aluminum alloy sacrificial anode series, zinc alloy sacrificial anode series, and cathodic protection supporting products, such as more than a dozen varieties and hundreds of specifications.

Focus on the development and production of cathodic protection materials

online message

We will contact you within one working day. Please pay attention to your phone or email.

Performance/Type/Index

Performance/Type/Index