Understanding the Science Behind Aluminum Anodes and Their Applications

Release time:

2025-12-14

Understanding the Science Behind Aluminum Anodes and Their Applications Table of Contents 1. Introduction to Aluminum Anodes 2. The Science of Corrosion and Protection 3. How Aluminum Anodes Work 4. Applications of Aluminum Anodes 4.1 Marine Industry 4.2 Industrial Applications 4.3 Construction and Infrastructure 5. Ad

Understanding the Science Behind Aluminum Anodes and Their Applications

Table of Contents

- 1. Introduction to Aluminum Anodes

- 2. The Science of Corrosion and Protection

- 3. How Aluminum Anodes Work

- 4. Applications of Aluminum Anodes

- 5. Advantages of Using Aluminum Anodes

- 6. Comparison with Other Anode Materials

- 7. Innovations in Aluminum Anode Technology

- 8. Frequently Asked Questions

- 9. Conclusion

1. Introduction to Aluminum Anodes

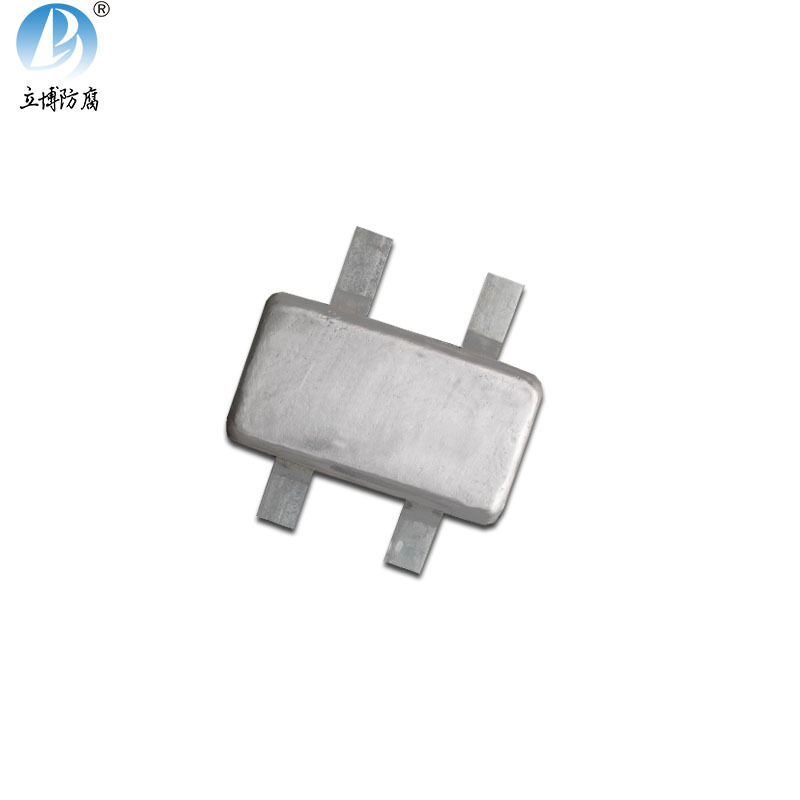

Aluminum anodes are essential components in the realm of corrosion prevention, widely used in various industries to safeguard metals from the detrimental effects of environmental conditions. These anodes function as sacrificial anodes, meaning they corrode in place of the metal components they protect, ensuring their longevity and functionality. Understanding the science behind aluminum anodes and their applications is crucial for professionals in construction, marine, and industrial settings.

2. The Science of Corrosion and Protection

Corrosion is a natural electrochemical process that occurs when metals react with moisture, air, and other environmental factors. This reaction leads to the deterioration of metal surfaces, resulting in significant economic losses and jeopardizing structural integrity. To counteract this phenomenon, cathodic protection systems, including aluminum anodes, are employed.

Cathodic protection involves using an anode and a cathode, where the anode (typically aluminum) corrodes preferentially to the cathode (the metal structure being protected). This process not only prevents the metal structure from rusting but also enhances its lifespan. The mechanics of this protection system hinge on the principles of electrochemistry, where electric currents are redirected to inhibit the corrosion process.

3. How Aluminum Anodes Work

The functionality of aluminum anodes is rooted in their electrochemical properties. When installed, aluminum anodes create a galvanic cell with the metal they are protecting. As the anode sacrifices itself, it releases electrons that travel through the electrolyte (water, soil, etc.) to the cathode, effectively neutralizing the corrosive reactions that would typically occur.

Aluminum is selected for anodes because of its lightweight nature, high electrical conductivity, and ability to generate a robust protective layer of aluminum oxide, which further enhances its protective capabilities. The use of aluminum anodes offers several advantages, including cost-effectiveness, ease of installation, and efficient corrosion protection.

4. Applications of Aluminum Anodes

Aluminum anodes are used across multiple sectors, each benefiting from their unique protective properties.

4.1 Marine Industry

In the marine environment, aluminum anodes protect boats, ships, and offshore structures from seawater corrosion. The harsh conditions of saltwater require robust protection mechanisms. Aluminum anodes are favored in this sector due to their effectiveness and lower weight compared to traditional zinc anodes. They protect critical components such as hulls, propellers, and underwater structures, significantly extending their operational lifespan.

4.2 Industrial Applications

Industrial facilities utilize aluminum anodes to protect pipelines, storage tanks, and other metallic structures from corrosion. In industries such as oil and gas, where infrastructure is often exposed to corrosive substances, the deployment of aluminum anodes serves as a critical measure for maintaining the integrity and safety of operations. These anodes ensure continuous protection, even in harsh environments.

4.3 Construction and Infrastructure

In construction, aluminum anodes are increasingly integrated into concrete structures, providing protection against the corrosion of reinforcement bars (rebar). The use of aluminum anodes in concrete helps mitigate one of the leading causes of structural failure, ensuring that buildings, bridges, and other infrastructures remain durable and safe over time.

5. Advantages of Using Aluminum Anodes

Aluminum anodes offer several advantages over alternative materials such as zinc and magnesium. These benefits include:

1. **Weight Efficiency**: Aluminum anodes are significantly lighter, making them easier to handle and install.

2. **Enhanced Durability**: They exhibit a more consistent corrosion rate, providing reliable protection over extended periods.

3. **Cost-Effectiveness**: Aluminum anodes are generally less expensive than other anode materials, making them a popular choice for businesses aiming to control costs without compromising on quality.

4. **Environmental Impact**: Aluminum is a sustainable material that can be recycled, minimizing the environmental footprint of anode production and disposal.

6. Comparison with Other Anode Materials

While aluminum anodes are widely used, it is essential to compare their effectiveness with alternatives such as zinc and magnesium anodes.

- **Zinc Anodes**: Often used for marine applications, zinc anodes are less expensive but can be heavier and less effective in certain environments, particularly where high salinity is present. They may corrode too quickly in some situations, requiring more frequent replacements.

- **Magnesium Anodes**: These are typically used in freshwater applications. Magnesium anodes offer a more significant driving potential but are unsuitable for saltwater environments, where they may sacrifice too quickly and lead to insufficient cathodic protection.

Overall, aluminum anodes provide a balanced approach, offering effective protection while minimizing weight and cost.

7. Innovations in Aluminum Anode Technology

The field of aluminum anode technology is continually evolving, driven by advancements in materials science and electrochemistry. Recent innovations include:

- **Composite Materials**: Researchers are exploring composite aluminum anodes that integrate additional protective elements to enhance performance and longevity.

- **Smart Anodes**: The development of smart anodes equipped with sensors allows for real-time monitoring of corrosion levels, enabling proactive maintenance strategies and optimizing the lifespan of protected structures.

- **Coatings and Surface Treatments**: Advanced coatings are being developed to enhance the electrochemical performance of aluminum anodes, providing better protection in diverse environments.

These innovations exemplify the ongoing efforts to improve anode technology and ensure effective corrosion prevention.

8. Frequently Asked Questions

1. What is the lifespan of aluminum anodes?

The lifespan of aluminum anodes varies based on environmental conditions and application but typically ranges from 3 to 5 years.

2. How do I know when to replace my aluminum anodes?

Replacement is necessary when the anode has corroded significantly (at least 50% consumed) or has developed pits or other issues indicating reduced effectiveness.

3. Are aluminum anodes environmentally safe?

Yes, aluminum is a non-toxic material that is safe for the environment. Additionally, it is recyclable, further minimizing environmental impact.

4. Can aluminum anodes be used in freshwater applications?

While aluminum anodes can be used in freshwater, their effectiveness may be lower compared to magnesium anodes, which are generally preferred in such environments.

5. How do I maintain aluminum anodes?

Regular inspections are essential. Ensure that anodes are clean and free of debris, and monitor for signs of corrosion to determine when replacements are necessary.

9. Conclusion

Understanding the science behind aluminum anodes reveals their critical role in preventing corrosion across various industries. With their lightweight, cost-effective, and eco-friendly properties, aluminum anodes have established themselves as vital components in marine, industrial, and construction applications. As technology continues to advance, the future of aluminum anodes looks promising, with innovations enhancing their performance and efficacy. By investing in high-quality aluminum anodes, industries can ensure the longevity and safety of their structures while minimizing maintenance costs and environmental impact.

Key words:

Learn more about industry dynamics

The company's main products: magnesium alloy sacrificial anode series, aluminum alloy sacrificial anode series, zinc alloy sacrificial anode series, and cathodic protection supporting products, such as more than a dozen varieties and hundreds of specifications.

Focus on the development and production of cathodic protection materials

online message

We will contact you within one working day. Please pay attention to your phone or email.