Understanding the Role of Magnesium Anodes in Corrosion Protection

Release time:

2025-07-13

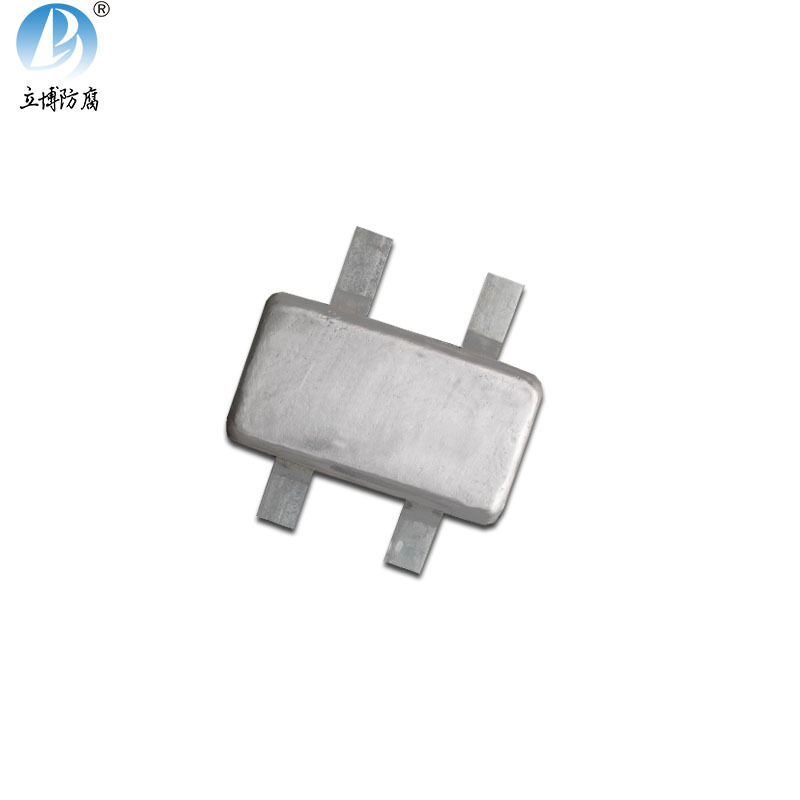

Magnesium anodes are essential components in the field of corrosion protection, particularly in industries that rely on metal structures. In the construction and decorative materials sector, the longevity and durability of materials are paramount. Corrosion can lead to significant structural failures, increased maintenance costs, and ultimately, safety hazards. This is where magnesium anodes come

Magnesium anodes function through a process known as cathodic protection. This method involves attaching a sacrificial anode, typically made of magnesium, to a metal structure. The magnesium anode serves as a sacrificial material, corroding preferentially to the underlying metal. By doing so, it diverts the corrosive effects away from the primary structure, helping to maintain its integrity over time.

One of the key advantages of magnesium anodes is their effectiveness in various environments, including freshwater and seawater applications. They are particularly beneficial in marine environments, where metal structures are highly susceptible to galvanic corrosion. The use of magnesium anodes in such settings can significantly prolong the lifespan of critical components, such as bridges, piers, and offshore platforms.

Moreover, magnesium anodes are lightweight and easy to install, making them a practical choice for many construction projects. Their affordability further enhances their appeal as a corrosion protection solution. Professionals in the construction and decorative materials industry will find that incorporating magnesium anodes into their projects can lead to reduced maintenance and repair costs in the long run.

It is also worth noting the importance of proper sizing and placement of magnesium anodes. Adequate coverage and positioning can ensure maximum protection against corrosion. Engineers and project managers must assess the specific requirements of their projects to determine the optimal number and size of anodes needed for effective corrosion mitigation.

In summary, magnesium anodes are a critical tool in the battle against corrosion in the construction and decorative materials industry. Their ability to provide sacrificial protection helps extend the life of metal structures, reduces maintenance costs, and enhances overall safety. As professionals continue to seek effective solutions for corrosion management, understanding and implementing magnesium anodes can be a game-changing strategy for prolonging the lifespan of numerous structures. Embracing this technology not only safeguards investments but also promotes sustainable practices in an era where material longevity is increasingly vital.

Key words:

Learn more about industry dynamics

The company's main products: magnesium alloy sacrificial anode series, aluminum alloy sacrificial anode series, zinc alloy sacrificial anode series, and cathodic protection supporting products, such as more than a dozen varieties and hundreds of specifications.

Focus on the development and production of cathodic protection materials

online message

We will contact you within one working day. Please pay attention to your phone or email.