Understanding Deep Well Anodes: Essential Knowledge for Corrosion Prevention in Construction

Release time:

2025-06-23

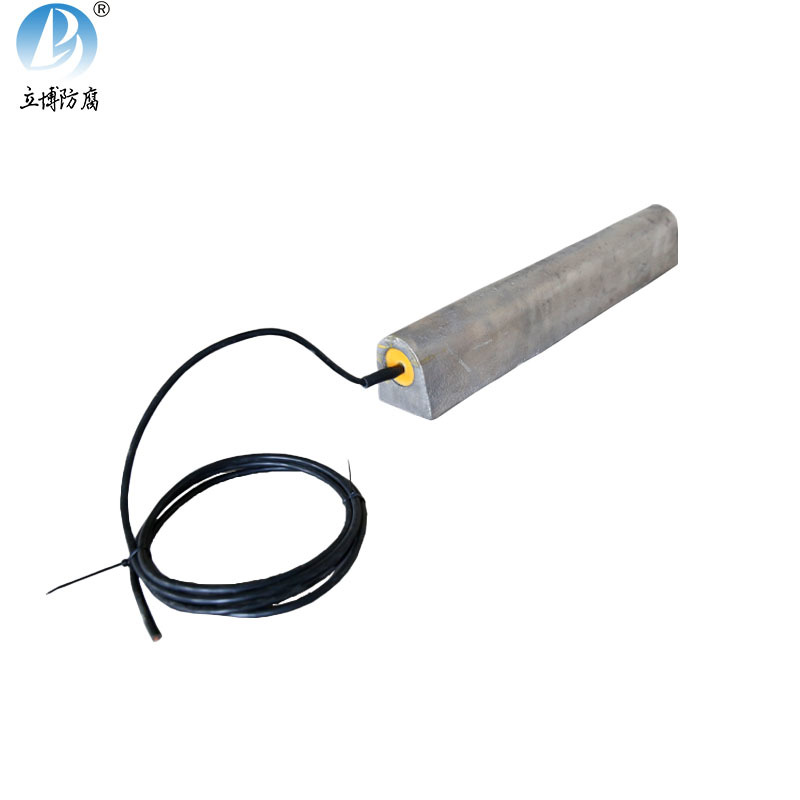

Deep well anodes are critical components in the fight against corrosion, particularly in environments where structures are exposed to moisture and electrolytic conditions. These anodes are designed to protect metallic structures, such as pipelines, tanks, and other buried installations, by providing a sacrificial element that mitigates corrosion damage. At their core, deep well anodes operate on t

At their core, deep well anodes operate on the principle of cathodic protection. When connected to a metal structure, the anode undergoes oxidation and corrodes instead of the protected metal. This process effectively extends the lifespan of the primary structure and reduces maintenance costs over time. The deeper installation of these anodes enhances their efficiency, as they can reach more stable soil conditions, which is crucial for consistent protection.

The construction industry benefits significantly from the use of deep well anodes. In environments such as coastal areas or regions with high water tables, where soil conductivity can lead to rapid corrosion, these anodes provide a reliable means of protection. They are especially useful in protecting reinforced concrete structures, which are susceptible to rusting of the steel reinforcement due to moisture ingress.

Installation of deep well anodes involves careful planning and execution. Professionals typically conduct soil resistivity tests to determine the most effective anode type and placement. The depth at which the anodes are installed can significantly influence their performance, as deeper placement may provide a more stable environment and better corrosion protection.

One of the advantages of using deep well anodes is their adaptability. They can be tailored to suit various applications and environmental conditions, ensuring effective corrosion prevention in diverse construction projects. Additionally, advancements in materials and technology have led to the development of more efficient anodes that offer longer service lives and improved performance.

In summary, understanding deep well anodes is essential for professionals in the construction and decorative materials industry. By leveraging the benefits of these corrosion prevention tools, companies can protect their investments, reduce maintenance frequency, and ultimately enhance the longevity of their structures. Investing in this knowledge not only aids in compliance with industry standards but also positions businesses as leaders in sustainable construction practices.

Key words:

Learn more about industry dynamics

The company's main products: magnesium alloy sacrificial anode series, aluminum alloy sacrificial anode series, zinc alloy sacrificial anode series, and cathodic protection supporting products, such as more than a dozen varieties and hundreds of specifications.

Focus on the development and production of cathodic protection materials

online message

We will contact you within one working day. Please pay attention to your phone or email.