How Aluminum Anodes Enhance the Longevity of Building Materials

Release time:

2025-06-08

How Aluminum Anodes Enhance the Longevity of Building Materials Table of Contents 1. Introduction to Aluminum Anodes 2. Understanding Corrosion and Its Impact on Building Materials 3. The Role of Aluminum Anodes in Corrosion Protection 4. Types of Aluminum Anodes Used in Construction 5. Application Methods for Aluminum Anodes 6. Benefits of Using Aluminum Ano

How Aluminum Anodes Enhance the Longevity of Building Materials

Table of Contents

- 1. Introduction to Aluminum Anodes

- 2. Understanding Corrosion and Its Impact on Building Materials

- 3. The Role of Aluminum Anodes in Corrosion Protection

- 4. Types of Aluminum Anodes Used in Construction

- 5. Application Methods for Aluminum Anodes

- 6. Benefits of Using Aluminum Anodes

- 7. Case Studies: Successful Implementation of Aluminum Anodes

- 8. Frequently Asked Questions (FAQs)

- 9. Conclusion

1. Introduction to Aluminum Anodes

In the construction industry, the durability and longevity of building materials are paramount. One effective solution to combat corrosion is the use of aluminum anodes. These sacrificial anodes play a significant role in protecting metal components, ensuring that structures maintain their integrity over time. This article delves into the mechanisms by which aluminum anodes enhance the longevity of building materials, exploring the benefits, applications, and success stories associated with their use.

2. Understanding Corrosion and Its Impact on Building Materials

Corrosion is a natural process that adversely affects metals, leading to deterioration and structural failure. It occurs when metals react with their environment, often resulting in the formation of rust and other corrosion byproducts. This degradation can significantly shorten the lifespan of building materials, from steel reinforcements to aluminum cladding, leading to costly repairs and safety concerns.

The Chemistry of Corrosion

The corrosion process involves electrochemical reactions between the metal and its surrounding environment. Factors such as moisture, oxygen, and pollutants can accelerate this degradation. Understanding these factors is crucial for implementing effective corrosion prevention strategies.

Types of Corrosion

Various types of corrosion can affect building materials, including:

- **Uniform Corrosion**: Evenly distributed over the material surface.

- **Pitting Corrosion**: Forms localized pits or holes, often hard to detect.

- **Galvanic Corrosion**: Occurs when two dissimilar metals are in contact, leading to accelerated degradation of one metal.

- **Crevice Corrosion**: Develops in hidden areas where moisture can accumulate.

3. The Role of Aluminum Anodes in Corrosion Protection

Aluminum anodes serve as a sacrificial metal that sacrifices itself to protect other metals in a structure from corrosion. This process is based on the principles of electrochemistry and galvanic protection.

How Aluminum Anodes Work

When aluminum anodes are installed, they corrode preferentially, thereby preventing the underlying metal (such as steel) from oxidizing. The aluminum anode creates a galvanic cell, redirecting the electrochemical reactions away from the more valuable structural metal.

Advantages of Aluminum for Anodes

Aluminum is lightweight, cost-effective, and has excellent corrosion resistance, making it an ideal choice for sacrificial anodes. Its ability to withstand harsh environmental conditions ensures prolonged protection for the building materials it safeguards.

4. Types of Aluminum Anodes Used in Construction

Various types of aluminum anodes are utilized in construction, each designed for specific applications and environments.

Extruded Aluminum Anodes

These anodes are shaped through an extrusion process, providing uniform density and surface area for effective corrosion protection. They are often used in marine applications and reinforced concrete structures.

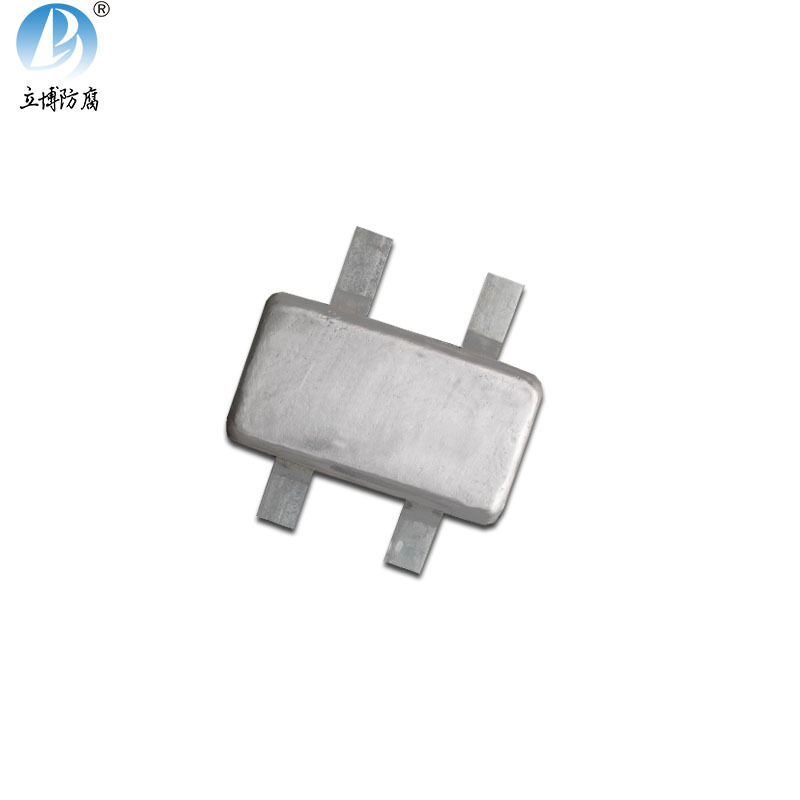

Cast Aluminum Anodes

Cast aluminum anodes are produced by pouring molten aluminum into molds. This method allows for the creation of complex shapes and sizes, making them suitable for various applications, including tanks and pipelines.

Aluminum Plates and Blocks

Flat plates and blocks of aluminum can be strategically placed in areas prone to corrosion, offering broad coverage and protection for large structures.

5. Application Methods for Aluminum Anodes

Correct installation and application of aluminum anodes are vital for their effectiveness in protecting building materials.

Placement Techniques

Anodes should be located in areas where corrosion is likely to occur, such as near waterlines, on steel reinforcements, and around structures exposed to moisture. Proper spacing and placement ensure that the protective current from the anodes reaches all critical areas.

Integration with Existing Structures

Incorporating aluminum anodes into existing structures can be accomplished through various methods, such as bolting or welding. Maintenance teams should assess the condition of existing materials before implementation to ensure maximum impact.

Regular Monitoring

Routine inspections and monitoring of aluminum anodes are essential to determine their effectiveness. This involves checking the level of corrosion on the anodes and ensuring that they are performing as designed.

6. Benefits of Using Aluminum Anodes

Implementing aluminum anodes in building materials provides numerous advantages that enhance structural longevity.

Cost-Effectiveness

Investing in aluminum anodes can lead to significant savings in maintenance and repair costs over time. By preventing corrosion, these anodes reduce the need for costly replacements and repairs.

Improved Safety

Corrosion can compromise the integrity of structures, posing safety risks. By utilizing aluminum anodes, builders can enhance safety by minimizing the risk of structural failure.

Environmental Benefits

Aluminum anodes are environmentally friendly, as they promote the longevity of materials, reducing waste. Their use contributes to sustainable construction practices and minimizes the environmental footprint of building projects.

7. Case Studies: Successful Implementation of Aluminum Anodes

Numerous successful projects illustrate the effectiveness of aluminum anodes in prolonging the lifespan of building materials.

Marine Structures

In coastal regions, marine structures such as docks and piers have benefited significantly from aluminum anodes. By preventing corrosion from saltwater exposure, these structures have experienced extended operational lifespans.

Bridges and Overpasses

Bridges utilizing aluminum anodes for their steel reinforcements have shown remarkable resistance to corrosion. These structures have maintained their integrity and safety over several decades, showcasing the long-term benefits of aluminum anode protection.

8. Frequently Asked Questions (FAQs)

1. What are aluminum anodes, and how do they work?

Aluminum anodes are sacrificial anodes designed to corrode preferentially, protecting other metals from corrosion. They create a galvanic cell that redirects the electrochemical reactions, preventing degradation of more valuable metals.

2. Where are aluminum anodes used?

Aluminum anodes are commonly used in marine applications, reinforced concrete structures, tanks, pipelines, and any areas where corrosion is a concern.

3. How long do aluminum anodes last?

The lifespan of aluminum anodes varies based on environmental conditions and the specific application. Regular monitoring can help determine when replacement is necessary.

4. Can aluminum anodes be reused?

Typically, aluminum anodes are not reusable due to their sacrificial nature. Once they have corroded to a certain extent, they should be replaced to ensure continued protection.

5. Are there alternatives to aluminum anodes?

Yes, alternatives include zinc and magnesium anodes; however, aluminum anodes are often preferred due to their lightweight, cost-effectiveness, and superior performance in various applications.

9. Conclusion

Aluminum anodes play a crucial role in enhancing the longevity of building materials by providing effective corrosion protection. Through the application of these sacrificial anodes, builders and maintenance teams can significantly reduce the risk of deterioration, ensuring the safety and durability of structures. As the construction industry continues to evolve, the integration of aluminum anodes represents a forward-thinking approach to sustainability and longevity. By adopting these practices, stakeholders can protect their investments while contributing to a more sustainable future in construction.

Key words:

Learn more about industry dynamics

The company's main products: magnesium alloy sacrificial anode series, aluminum alloy sacrificial anode series, zinc alloy sacrificial anode series, and cathodic protection supporting products, such as more than a dozen varieties and hundreds of specifications.

Focus on the development and production of cathodic protection materials

online message

We will contact you within one working day. Please pay attention to your phone or email.