Why Choose Irregular Zinc Anodes for Your Construction Projects?

Release time:

2025-04-30

Why Choose Irregular Zinc Anodes for Your Construction Projects? In the world of construction, the integrity and longevity of materials are paramount. Among various protective measures, the use of anodes plays a crucial role in preventing corrosion, especially in structures exposed to moisture and harsh environments. This article delves into the compelling reasons why irregular zinc anodes are an

Why Choose Irregular Zinc Anodes for Your Construction Projects?

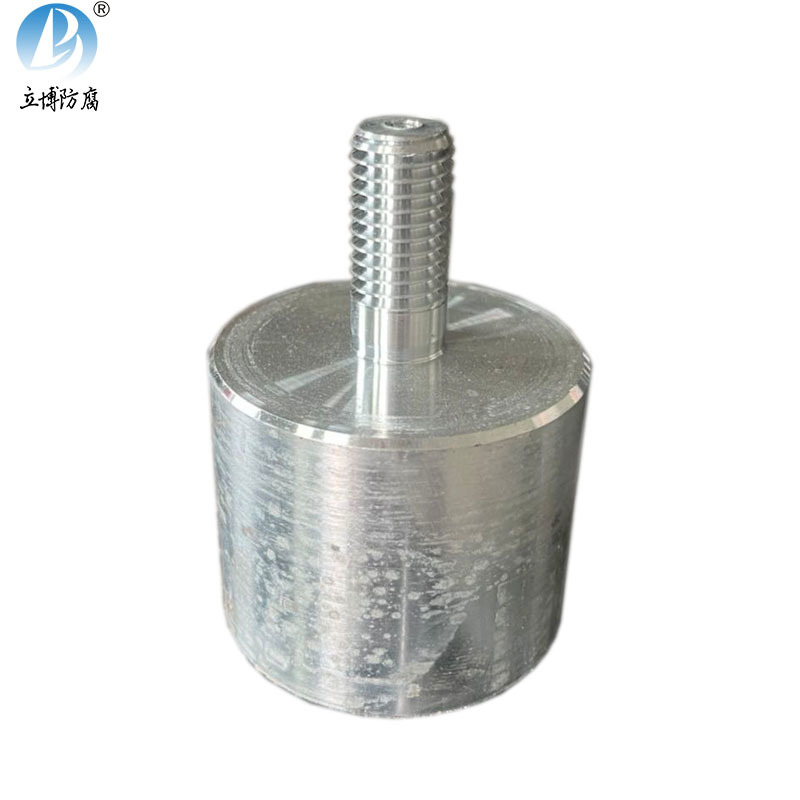

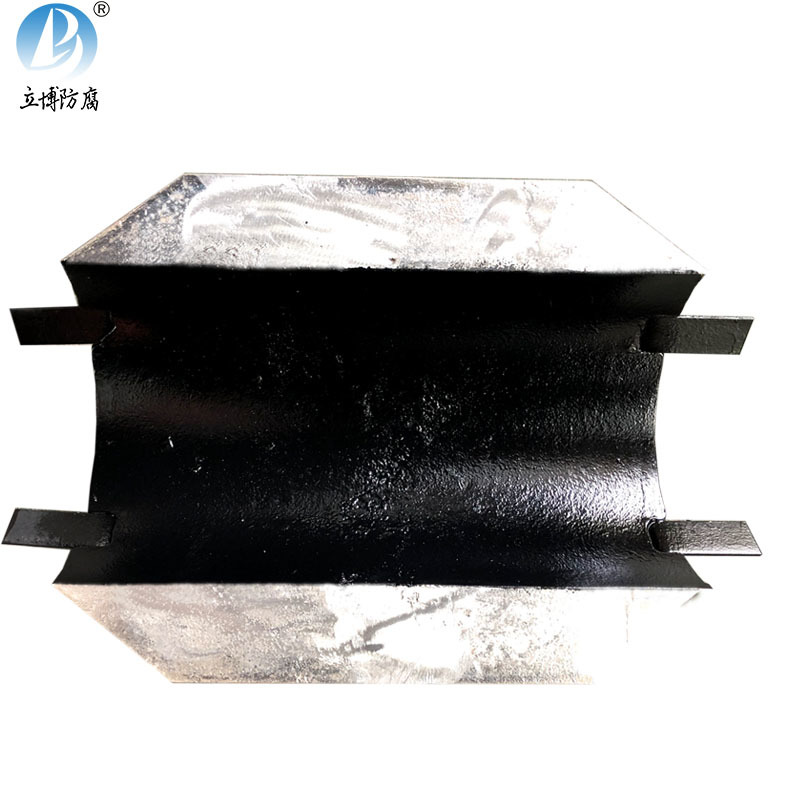

In the world of construction, the integrity and longevity of materials are paramount. Among various protective measures, the use of anodes plays a crucial role in preventing corrosion, especially in structures exposed to moisture and harsh environments. This article delves into the compelling reasons why irregular zinc anodes are an optimal choice for your construction projects, detailing their benefits, applications, and the science behind their effectiveness.

Understanding Zinc Anodes and Their Role in Construction

Before exploring the unique advantages of irregular zinc anodes, it’s essential to understand what they are and how they function. Zinc anodes are sacrificial anodes made from zinc metal, primarily used to protect other metal structures from corrosion through a process known as cathodic protection. When exposed to moisture or electrolytic conditions, the zinc anodes corrode preferentially, thereby extending the life of the underlying metal components.

The Science Behind Corrosion Protection

Corrosion is a natural process that occurs when metals react with environmental factors such as water, oxygen, and salts. The electrochemical reactions that lead to corrosion can be mitigated by using sacrificial anodes. In a cathodic protection system, the irregular zinc anodes provide a constant supply of electrons, thus preventing the corrosion of more valuable structures such as steel, copper, and aluminum.

Advantages of Using Irregular Zinc Anodes

1. Enhanced Surface Area for Optimal Protection

One of the most significant advantages of irregular zinc anodes is their enhanced surface area. Unlike traditional, uniform anodes, irregular shapes allow for more efficient electron distribution. This variability ensures that every exposed area of the anode contributes to corrosion prevention, providing more comprehensive protection for your construction materials.

2. Improved Adhesion and Integration

The unique shapes of irregular zinc anodes allow for better mechanical interlocking with the substrate material. This characteristic leads to improved adhesion, making them particularly effective in harsh environments where traditional anodes might fail. The secure integration of these anodes into constructions ensures that they remain in place and function correctly over extended periods.

3. Cost-Effectiveness in the Long Run

While the initial investment in irregular zinc anodes may be higher than conventional options, their long-term benefits far outweigh the costs. Their durability reduces the frequency of replacements and maintenance interventions, ultimately leading to lower overall expenses. For construction projects, this translates into significant savings and a higher return on investment.

4. Versatile Applications Across Various Projects

Irregular zinc anodes are not limited to specific types of construction projects. Their versatility allows them to be utilized in a range of applications, including:

- Marine Infrastructure: Protecting piers, docks, and vessels exposed to corrosive seawater.

- Bridges and Overpasses: Ensuring the longevity of metal components subject to environmental wear.

- Underground Structures: Safeguarding pipelines and tanks that encounter moisture.

5. Environmental Benefits and Sustainability

In today’s construction industry, sustainability is more important than ever. Irregular zinc anodes contribute to environmentally friendly practices by prolonging the life of structures and reducing the need for replacements. Additionally, zinc is a recyclable material, making it a sustainable choice in construction projects.

Choosing the Right Irregular Zinc Anodes for Your Project

Factors to Consider When Selecting Anodes

When selecting irregular zinc anodes for your construction project, consider the following factors:

- Environmental Conditions: Assess the corrosive nature of the environment and choose anodes that can withstand these conditions.

- Size and Shape: Evaluate the geometry of the structures requiring protection to determine the most suitable anode configuration.

- Compatibility: Ensure that the anodes are compatible with the metals they are intended to protect.

Installation Best Practices

Proper installation is critical for maximizing the effectiveness of irregular zinc anodes. Follow these best practices:

- Surface Preparation: Clean the surface thoroughly to eliminate contaminants that could hinder adhesion.

- Correct Placement: Position the anodes in areas where they can provide the most benefit, ensuring optimal coverage.

- Regular Inspections: Conduct routine checks to assess the condition of the anodes and replace them as needed.

Frequently Asked Questions (FAQs)

1. What makes irregular zinc anodes different from traditional anodes?

Irregular zinc anodes have unique shapes that enhance surface area and improve adhesion, allowing for more effective corrosion protection compared to traditional, uniform anodes.

2. How long do irregular zinc anodes last?

The lifespan of irregular zinc anodes depends on factors such as environmental conditions and the quality of installation. Properly installed anodes can last several years, significantly extending the life of protected structures.

3. Can irregular zinc anodes be used in freshwater environments?

Yes, irregular zinc anodes can be used in freshwater environments. They provide effective corrosion protection for metal components that are submerged or exposed to moist conditions.

4. Are there any specific regulations regarding the use of zinc anodes?

Construction projects must adhere to local and national regulations regarding material use and corrosion protection. It's essential to consult with professionals to ensure compliance with relevant standards.

5. Can I install irregular zinc anodes myself?

While installation can be done by experienced individuals, it is recommended to hire professionals to ensure correct placement and adherence to best practices for maximum efficacy.

Conclusion

Choosing irregular zinc anodes for your construction projects presents a myriad of advantages, from enhanced corrosion protection to long-term cost savings and environmental benefits. Their unique characteristics, such as improved surface area and better adhesion, make them a superior choice for safeguarding structures in various conditions. As the construction industry continues to prioritize sustainability and durability, irregular zinc anodes stand out as a reliable and effective solution. By integrating these anodes into your projects, you can ensure the longevity and integrity of your construction, ultimately leading to successful outcomes and satisfied stakeholders.

Key words:

Learn more about industry dynamics

The company's main products: magnesium alloy sacrificial anode series, aluminum alloy sacrificial anode series, zinc alloy sacrificial anode series, and cathodic protection supporting products, such as more than a dozen varieties and hundreds of specifications.

Focus on the development and production of cathodic protection materials

online message

We will contact you within one working day. Please pay attention to your phone or email.