Understanding Cylindrical Magnesium Anodes: Essential Components in Corrosion Prevention

Release time:

2025-04-18

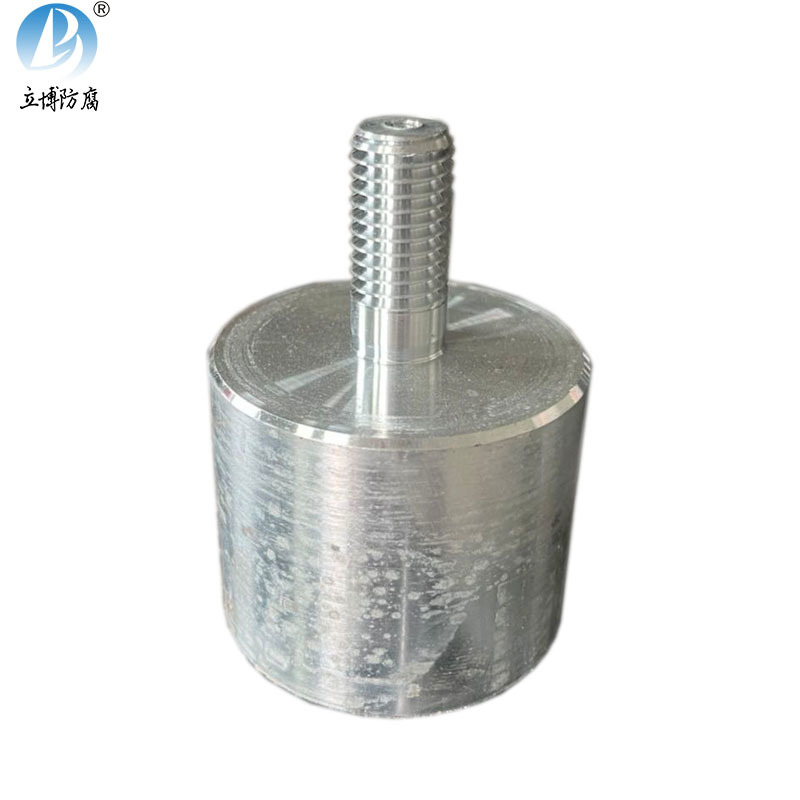

Cylindrical magnesium anodes are specialized components utilized primarily for cathodic protection in various applications, including marine environments, pipelines, and storage tanks. These anodes are made from high-purity magnesium, which is a highly reactive metal, making it an ideal choice for protecting other metals from corrosion. The fundamental principle behind the operation of a magnesium

The use of cylindrical magnesium anodes is widespread due to their efficient design and ease of installation. Their cylindrical shape allows for uniform distribution of the protective current, enhancing the effectiveness of the anode. This design is particularly beneficial in applications where space is limited or where multiple anodes are required. The anodes are typically installed in proximity to the metal structures they are intended to protect, ensuring optimal performance.

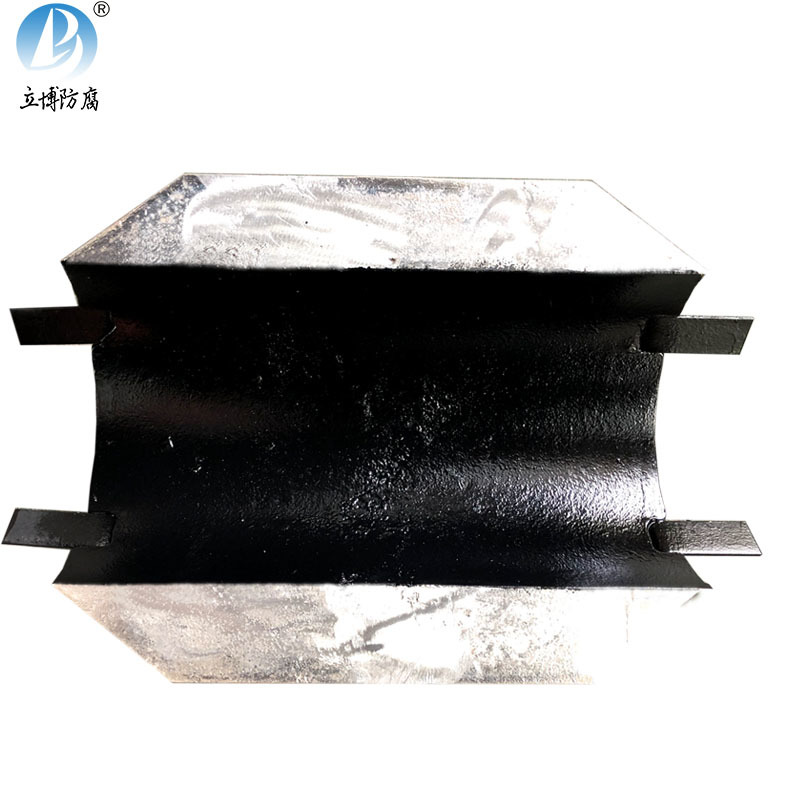

One of the standout features of cylindrical magnesium anodes is their ability to function effectively in various environments, including freshwater and seawater. Their performance is influenced by factors such as temperature, salinity, and the specific type of metal being protected. This versatility makes them an essential choice for industries such as oil and gas, marine engineering, and infrastructure maintenance.

Moreover, the environmental benefits of using magnesium anodes cannot be overstated. Magnesium is a more environmentally friendly option compared to other materials, such as zinc or aluminum, as it is more abundant and less toxic. This characteristic aligns with the growing emphasis on sustainable practices in various industries, making magnesium anodes a preferred choice for eco-conscious professionals.

In addition to their protective properties, cylindrical magnesium anodes are also cost-effective. While the initial investment might be comparable to other cathodic protection systems, the long-term savings associated with reduced maintenance and increased lifespan of the protected structures make them an economically viable option. This aspect is particularly appealing to industries where operational efficiency and cost management are paramount.

In conclusion, cylindrical magnesium anodes serve as vital components in the fight against corrosion, offering a combination of effectiveness, environmental sustainability, and cost efficiency. For professionals in the metallurgy, mining, and energy sectors, understanding the applications and benefits of these anodes can lead to better decision-making and enhanced protection of critical assets. By integrating cylindrical magnesium anodes into corrosion management strategies, businesses can ensure the longevity and reliability of their infrastructure.

Key words:

Learn more about industry dynamics

The company's main products: magnesium alloy sacrificial anode series, aluminum alloy sacrificial anode series, zinc alloy sacrificial anode series, and cathodic protection supporting products, such as more than a dozen varieties and hundreds of specifications.

Focus on the development and production of cathodic protection materials

online message

We will contact you within one working day. Please pay attention to your phone or email.