Quality Assurance

Supports multiple specifications customization

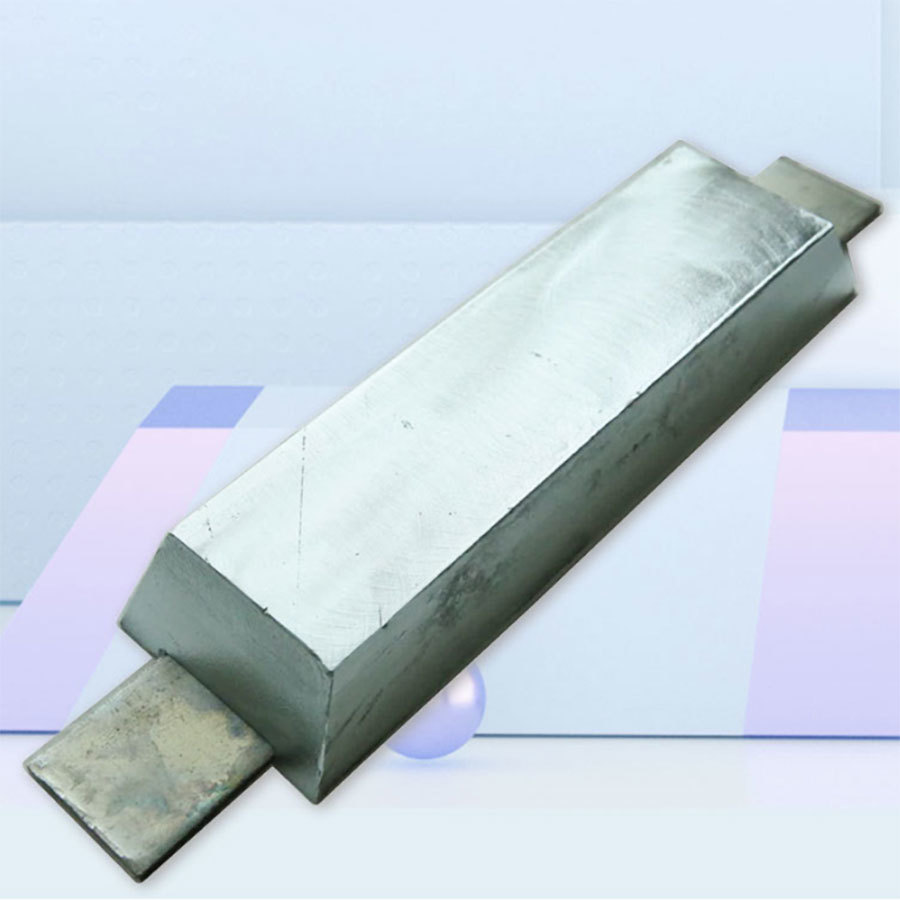

Durable Disc Zinc Anode

Release time:

2025-05-14

One of the key benefits of the Disc Zinc Anode is its ability to extend the lifespan of your equipment and reduce long-term maintenance costs. By absorbing corrosive elements, it preserves the structural integrity of metal parts, ensuring optimal performance over time.

Product Parameters

Execution Standard:GB/T4950-2021 GB/T21448-2017

Main Performance: Low anode self-dissolution, high current efficiency, good self-regulation performance of anode current; long protection lifespan, up to 20-30 years, generally no 'over-protection' phenomenon occurs.

Applicable Scope:Zinc alloy sacrificial anodes are suitable for cathodic protection of metals in seawater, brackish water media, ships, ballast water tanks, mechanical equipment, marine engineering and port facilities, drilling platforms, port docks, seawater medium condensers, water pumps, and pipelines, cables, etc. in low resistivity soil.

Product Features:Zinc-aluminum-cadmium (ZAC) sacrificial anodes are cast from high-purity zinc and aluminum, cadmium alloy. This product is recognized by the China Classification Society (CCS), and the quality standards meet GB/T4950-2021 standards. The chemical composition of zinc anodes complies with USMIL-A-18001H and ASTM+B418 (Type 1) standards. The anodes for pipelines also comply with GB/T21448-2017 'Design Specification for Cathodic Protection of Buried Steel Pipelines with Sacrificial Anodes'. Different specifications and sizes can be customized according to customer requirements!

Zinc-aluminum-chromium alloy sacrificial anode

Chemical Composition

Chemical Elements | AI | Cd | Impurities not greater than | Zn | |||

Fe | Cu | Pb | Si | ||||

Content % | 0.3-0.6 | 0.05-0.12 | 0.005 | 0.005 | 0.006 | 0.125 | Remainder |

Electrochemical Performance

| Open Circuit Potential | Working Potential | Actual Electric Capacity | Current Efficiency | Dissolution Condition |

In Seawater | -1.09~-1.05 | -1.05~-1.00 | ≥780 | ≥95 | Corrosion products are easy to detach |

In Soil | ≤-1.05 | ≤-1.03 | ≥530 | ≥65 |

Common Sacrificial Anode Models and Specifications for Hulls

Model | Specification | Weight (kg) |

Length*Width*Height (mm) | ||

ZH-1 | 800*140*60 | 47.0 |

ZH-2 | 800*140*50 | 39.0 |

ZH-3 | 800*140*40 | 31.0 |

ZH-4 | 600*120*50 | 25.0 |

ZH-5 | 400*120*50 R | 16.0 |

ZH-6 | 500*100*40 | 13.6 |

ZH-7 | 400*100*40 | 11.0 |

ZH-8 | 300*100*40 | 7.5 |

ZH-9 | 250*100*40 | 6.5 |

ZH-10 | 180*70*40 | 3.5 |

ZH-11 | 300*150*50 Double Iron Legs | 14.5 |

ZH-12 | 300*150*40 Double Iron Legs | 11.5 |

ZH-13 | 300*150*50 Bolt Type | 12.0 |

ZH-14 | 300*150*40 Bolt Type | 9.0 |

Common Sacrificial Anode Models and Specifications for Port Facilities and Marine Engineering

Model |

| Weight (kg) |

Length*(Upper Base + Lower Base)*Height (mm) | ||

ZI-1 | 1000*(115*135)*130 | 115.0 |

ZI-1 | 750*(115+135)*130 | 85.0 |

ZI-1 | 500*(115+135)*130 | 56.0 |

ZI-1 | 500*(105+135)*100 | 40.0 |

Common Sacrificial Anode Models and Specifications for Ballast Water Tanks

Model | Specification | Weight (kg) |

Length*(Upper Base + Lower Base)*Height (mm) | ||

ZT-1 | 500*(115+135)*130 | 56.0 |

ZT-2 | 1500*(65+75)*70 | 50.0 |

ZT-3 | 500*(110+130)*120 | 50.0 |

ZT-4 | 1000*(58.5+78.5)*68 | 33.0 |

ZT-5 | 800*(56+74)*65 | 25.0 |

ZT-6 | 1150*(48+54)*51 | 20.0 |

ZT-7 | 250*(80+100)*85 | 13.0 |

ZT-8 | 200*(70+90)*70 | 7.5 |

Bracelet Type Zinc Alloy Anode Models and Specifications

Model | Specification | Weight (kg) |

Inner diameter * Width * Thickness * Gap mm | ||

ZZ-1 | 1020*200*35*51 | 179.5 |

ZZ-2 | 819*60*30*51 | 34.5 |

ZZ-3 | 624*80*30*51 | 45.0 |

ZZ-4 | 513*100*30*51 | 45.0 |

ZZ-5 | 280*250*45*51 | 76.5 |

ZZ-6 | 252*250*45*51 | 68.5 |

Common sacrificial anode model specifications for storage tanks

Model | Specification R | Weight (kg) |

Length*(Upper Base + Lower Base)*Height (mm) | ||

ZC-1 | 750*(115+135)*130 | 85.0 |

ZC-2 | 500*(115+135)*130 | 56.0 |

ZC-3 | 500*(105+135)*100 | 40.0 |

ZC-4 | 300*(105+135)*100 | 25.0 |

Common long strip sacrificial anode model specifications and common disc-shaped sacrificial anode model specifications for seawater cooling water systems

Model | Specification | Weight (kg) |

Length*(Upper Base + Lower Base)*Height (mm) | ||

ZE-1 | 500*(115+135)*130 | 56.0 |

ZE-2 | 1000*(80+100)*80 | 50.0 |

ZE-3 | 500*(105+135)*100 | 40.0 |

ZE-4 | 500*(80+100)*80 | 25.0 |

ZE-5 | 400*(110+120)*50 | 16.0 |

ZE-6 | 300*(140+160)*40 | 12.5 |

ZE-7 | 200*(90+110)*40 | 5.5 |

Model | Diameter * Height (mm) | Weight (kg) |

ZE-8 | 300*60 disc-shaped | 30.0 |

ZE-9 | 360*40 disc-shaped | 28.5 |

ZE-10 | 300*40 disc-shaped | 20.0 |

ZE-11 | 200*50 disc-shaped | 10.5 |

ZE-12 | 180*50 disc-shaped | 8.5 |

ZE-13 | 120*100 disc-shaped | 7.5 |

Common sacrificial anode model specifications for buried pipelines, storage tank outer walls, and other underground metal structures

Model | Specification | Weight (kg) |

Length*(Upper Base + Lower Base)*Height (mm) | ||

ZP-1 | 1000*(78+88)*85 | 50.0 |

ZP-2 | 1000*(65+75)*65R | 33.0 |

ZP-3 | 800*(60+80)*65 | 25.0 |

ZP-4 | 800*(55+64)*60 | 22.0 |

ZP-5 | 650*(58+64)*60 | 18.0 |

ZP-6 | 550*(58+64)*60 | 15.0 |

ZP-7 | 600*(52+56)*54 | 12.5 |

ZP-8 | 600*(40+48)*45 | 9.0 |

One of the key benefits of the Disc Zinc Anode is its ability to extend the lifespan of your equipment and reduce long-term maintenance costs. By absorbing corrosive elements, it preserves the structural integrity of metal parts, ensuring optimal performance over time. This makes it a cost-effective solution for both commercial and recreational marine users.

Whether you need protection for a propeller shaft, hull, or underwater machinery, the Disc Zinc Anode delivers trusted, efficient results. Its robust design, strong anti-corrosion capabilities, and easy installation make it a preferred choice for those seeking long-lasting protection in demanding environments.

Choose the Disc Zinc Anode for superior defense against corrosion and peace of mind on the water. Built to perform, built to last.

Key words:

Learn more about industry dynamics

The company's main products: magnesium alloy sacrificial anode series, aluminum alloy sacrificial anode series, zinc alloy sacrificial anode series, and cathodic protection supporting products, such as more than a dozen varieties and hundreds of specifications.

Focus on the development and production of cathodic protection materials

online message

We will contact you within one working day. Please pay attention to your phone or email.

Performance/Type/Index

Performance/Type/Index